1/ Definition and Scope of Mechanical Engineering

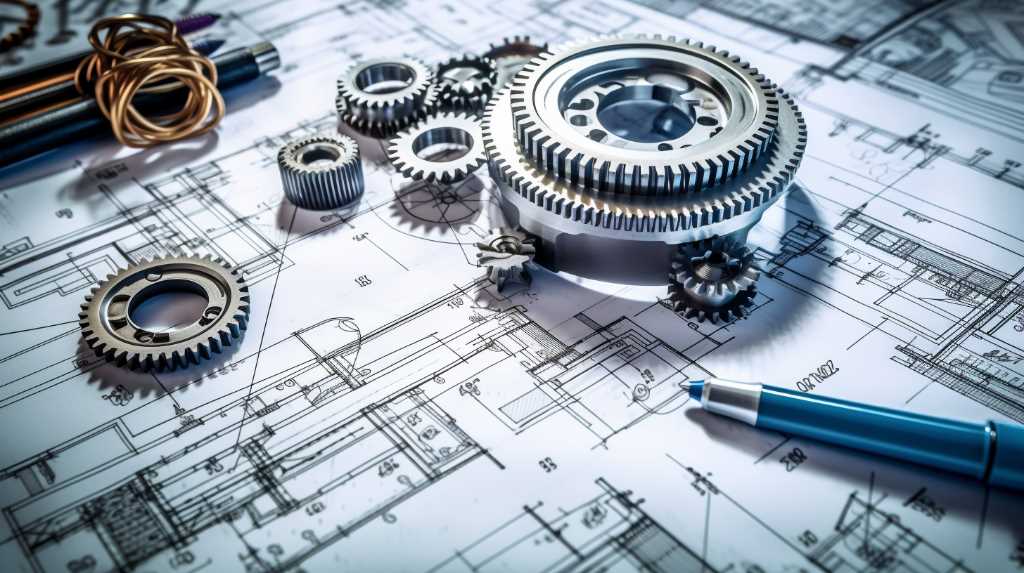

Mechanical engineering is the branch of engineering that focuses on the design, analysis, manufacturing, and maintenance of mechanical systems. It combines principles of physics, mathematics, and material science to develop solutions that enhance efficiency, productivity, and comfort across a vast array of applications.

This discipline spans from conceptual design - where engineers use scientific laws to create machines - to hands-on fabrication and testing. It serves as a bridge between innovative ideas and practical devices, ensuring that products operate safely, reliably, and cost-effectively.

2/ Core Disciplines of Mechanical Engineering

Mechanical engineering rests on several fundamental principles:

- Statics and Dynamics: analysis of forces on structures at rest and in motion

- Thermodynamics: relationships between heat, work, and energy conversion

- Fluid Mechanics: behavior of liquids and gases in systems like pumps and pipelines

- Material Science: selection and characterization of materials for strength, durability, and cost

- Mechanics of Materials: study of stress, strain, and failure in components

These disciplines equip engineers to solve complex mechanical problems, from calculating load paths in bridges to optimizing heat transfer in engines.

3/ Design and Manufacturing Processes

- Computer-Aided Design (CAD): creation of precise 2D and 3D models for visualization and simulation

- Computer-Aided Manufacturing (CAM): programming CNC machines for high-precision cutting, milling, and turning

- Computer-Aided Engineering (CAE): virtual testing of stress, thermal behavior, and fluid flow before production

- Product Lifecycle Management (PLM): overseeing a product’s journey from initial concept through maintenance and disposal

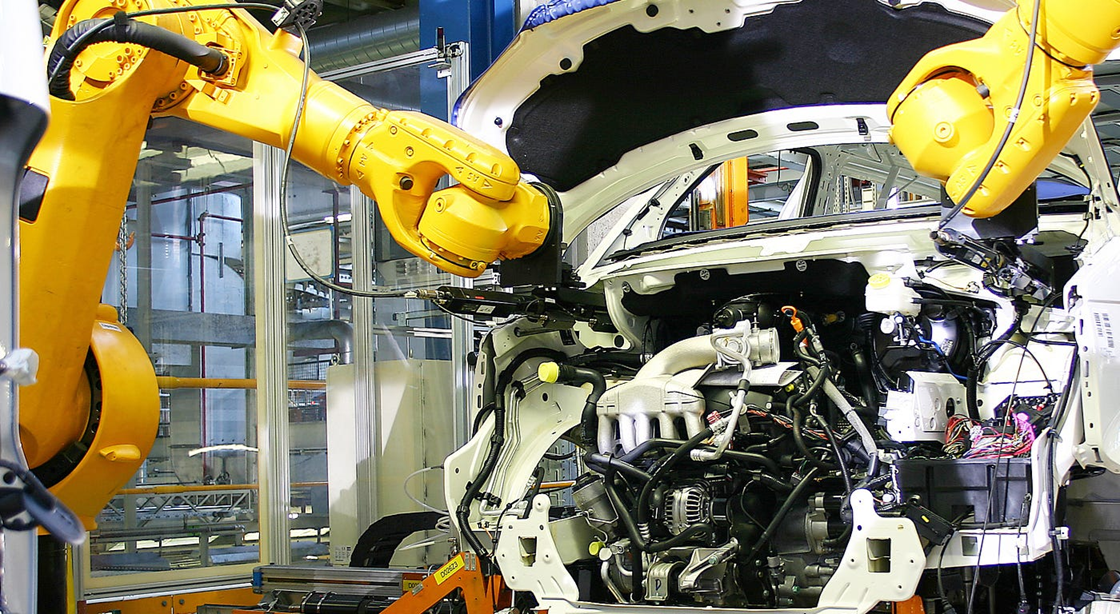

- Advanced Fabrication Techniques: CNC automation, additive manufacturing (3D printing), and robotic assembly lines to boost accuracy and throughput

These processes reduce prototyping time, lower material waste, and ensure consistent quality in mass production.

4/ Role in Key Industries

|

Industry |

Key Applications |

|---|---|

|

Manufacturing |

CNC machining; automated robotic cells; precision tooling |

|

Automotive |

Engine and transmission design; chassis dynamics; crash-energy management |

|

Aerospace |

Turbine and propulsion systems; structural weight optimization; flight control mechanisms |

|

Energy |

Wind turbine rotor and gearbox design; power plant turbines; HVAC and refrigeration systems |

|

Healthcare |

Medical imaging equipment; surgical robots; prosthetic and orthotic device development |

|

Cranes and lifting equipment; HVAC ductwork and controls; pre-fabricated structural components |

Mechanical engineering innovations underpin these sectors, driving higher performance, lower costs, and enhanced safety.

5/Applications in Daily Life

- Household Appliances: washing machines, refrigerators, and air conditioners use mechanical systems for efficient operation.

- Personal Transport: bicycles, motorcycles, and cars rely on engine design, suspension, and braking systems developed by mechanical engineers.

- Infrastructure and Buildings: elevators, escalators, heating and cooling installations ensure comfort and accessibility in homes and workplaces.

- Safety Equipment: mechanical designs in helmets, power-tool safeguards, and emergency shut-off valves protect users from hazards.

These everyday technologies illustrate how mechanical engineering enhances convenience, mobility, and well-being.

6/ Future Trends and Sustainable Development

Mechanical engineering is evolving rapidly to meet sustainability and industry 4.0 goals:

- Internet of Things (IoT) and Digital Twins: real-time monitoring and virtual replicas enable predictive maintenance and energy optimization.

- Artificial Intelligence and Robotics: smart automation systems learn to self-adjust processes, reducing downtime and human exposure to risks.

- Additive Manufacturing and Advanced Materials: 3D printing with metal alloys and composites allows lightweight, high-strength parts with minimal waste.

- Circular Economy Practices: designing for disassembly, refurbishing used components, and recycling metals support closed-loop manufacturing.

These trends position mechanical engineering at the heart of green factories, smart cities, and resilient supply chains that balance economic growth with environmental stewardship

7/ The Importance of Mechanical Engineering in Sustainable Development

Mechanical engineering drives sustainable development by designing systems and processes that minimize environmental impact, conserve resources, and support long-term economic growth.

7.1/ Reducing Environmental Impact

Mechanical engineers optimize designs to lower emissions, limit waste, and protect ecosystems. They:

- Develop high-efficiency motors, turbines, and compressors to cut greenhouse gas output

- Implement closed-loop cooling and filtration systems to prevent water and air pollution

- Integrate lightweight materials and aerodynamic shapes to reduce fuel consumption in transportation

7.2/ Enhancing Resource and Energy Efficiency

Efficient machines and processes are central to sustainability. Through advanced controls and smart monitoring, mechanical engineering enables:

- Real-time energy management via sensor networks and IoT platforms

- Waste heat recovery systems that convert lost thermal energy into electricity or heating

- Precision manufacturing techniques that eliminate excess material usage and scrap

7.3/ Enabling a Circular Economy

Mechanical engineering supports product lifecycles that emphasize reuse and recycling:

- Designing modular products for easy disassembly and component replacement

- Applying additive manufacturing (3D printing) to fabricate parts with minimal material waste

- Establishing metal reclamation processes that recover alloys from end-of-life equipment

7.4/ Fostering Technological Innovation

Cutting-edge mechanical solutions accelerate the transition to green industries:

- Autonomous and adaptive robotics that optimize production lines for low energy use

- Use of advanced composites and nanomaterials for stronger, lighter, and more durable components

- Digital twin simulations that predict maintenance needs and extend machinery lifespan

7.5/ Delivering Socioeconomic Benefits

By improving safety, reducing costs, and creating new industries, mechanical engineering contributes to social well-being:

- Safer workplaces with automation of hazardous tasks

- Job creation in renewable energy, sustainable transport, and green manufacturing

- Enhanced quality of life through reliable water treatment, efficient heating and cooling, and clean power generation

8/ Conclusion

Mechanical engineering lies at the heart of sustainable development, balancing technical innovation with ecological stewardship. As the discipline embraces digitalization, advanced materials, and circular-economy principles, it will continue to shape a cleaner, more resilient future.

Visit qtetech.com/en to choose from a wide range of machinery and mechanical components from many famous brands around the world.

QTE Technologies is a proud global MRO provider serving customers in over 180 countries and always striving to ensure a complete and satisfying customer experience. Established in 2010, we offer over 1 million products across every industry and technology. Additionally, you can reach us anytime via 24×7 chat support, phone, WhatsApp or email. Discover what our valued customers have to say about our services on our dedicated review page.

Author of the article: Editorial Board of QTE Technologies (with a solid background in both engineering and creativity - accumulated over 15 years of experience).