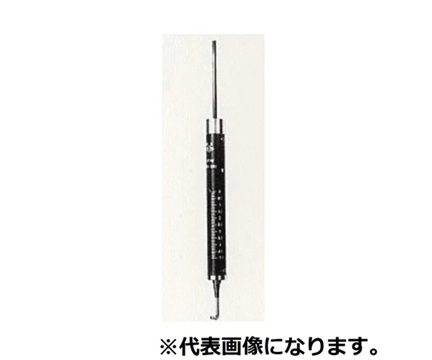

Oba Keiki Seisakusho, K. K. 0114-01-0002090 Rod Tension Gauge (10kg, O-BT100N)

| Manufaturer: | Oba Keiki Seisakusho, K. K. |

| Model: | 0114-01-0002090 |

*The above price is Standard Price, Kindly click on Request a quote to unlock the Best Price and Delivery Date. Our expert consulting team is always ready to assist you.

*Order Process: 1. Request a quote ⇒ 2. Quote via Email ⇒ 3. Proforma Invoice ⇒ 4. Payment ⇒ 5. Delivery and Invoice.

*You can't find the product you need, please send us the picture/specifications/model/product code and quantity you need to email: [email protected]. We will find it for you.

*Review us here: Review Now

Description

- Type: Standard

- Scale: 0, 25N

- Horizontal scale error: 0, 35N

- Code number: 119-0165036

-

Frequently Asked Questions about the Rod-Type Tension Gauge (10 kg, O-BT100N) Oba Keiki Seisakusho, K.K. (0114-01-0002090):

1. General Information

-

Q: What is the O-BT100N tension gauge? A: The O-BT100N is a rod-type spring tension gauge designed to measure pull and push forces up to 100 N (approximately 10 kgf).

-

Q: Who is Oba Keiki Seisakusho, K.K.? A: Oba Keiki is a Japanese manufacturer specializing in mechanical force and pressure measurement instruments. Their products comply with JIS and ISO quality standards.

-

2. Technical Specifications

-

Q: What does the model number O-BT100N signify? A: “O-BT” indicates Oba Keiki’s rod-type tension gauge series, while “100N” denotes a maximum capacity of 100 Newtons.

-

Q: What is the measurement range, unit, and resolution? A: Range: 0–100 N. Unit: Newton (N). Minimum graduation: 1 N.

-

Q: What accuracy does it offer? A: ±1 graduation under vertical measurement conditions.

-

Q: Which standards and origin apply? A: Conforms to Japanese Industrial Standards (JIS) and is manufactured in Japan.

-

Q: What are its dimensions and weight? A: Rod length ~180 mm; total weight ~200 g—compact and handheld.

-

3. Applications

-

Q: Which materials can be tested? A: Springs, small steel cables, ropes, O-rings, thin metal rods, fiber strands, and similar items.

-

Q: In which industries is it commonly used? A: Mechanical manufacturing, automotive/motorcycle assembly, electronics production, spring inspection, and cable tension testing.

-

Q: Can it measure both tensile and compressive forces? A: Yes. By reversing the rod orientation, it measures pull (tension) and push (compression) forces.

-

4. Operation

-

Q: How do I read the scale? A: Align the rod with the zero mark, apply force steadily, and read the peak needle position as the force value.

-

Q: Is zero-point adjustment necessary? A: Yes. Use the zero-adjust knob to bring the pointer to zero before each measurement for best accuracy.

-

Q: How do I correct horizontal measurement errors? A: Refer to the provided horizontal error correction chart and add the specified correction to your reading.

-

Q: Does the force application speed matter? A: Applying force slowly and evenly minimizes pointer oscillation and yields more stable readings.

-

5. Maintenance & Calibration

-

Q: How should I store and care for the O-BT100N? A: Store in a dry, dust-free environment. After use, wipe off debris and apply a thin film of light oil to prevent rust.

-

Q: When is calibration required? A: Every 6–12 months or after 1,000–2,000 measurement cycles, depending on usage intensity.

-

Q: What is the calibration procedure? A: Use a certified force standard or send the gauge to an authorized calibration laboratory for verification and adjustment.

-

6. Purchasing & Warranty

-

Q: What is the typical price range? A: Please contact QTE Technologies

-

Q: Where can I buy an authentic O-BT100N? A: Please contact QTE Technologies.

-

Q: What warranty is provided? A: Please contact QTE Technologies.

-

7. Model Comparison & Selection

-

Q: When should I choose the O-BT100N over other gauges? A: Select the O-BT100N for simple, manual measurements up to 100 N without digital readout. For lower ranges, consider O-BT10N; for higher, O-BT300N or O-BT500N.

-

Q: What are the pros and cons of a mechanical rod-type gauge vs. an electronic gauge?

-

Advantages:

-

Portable and power-free

-

Immediate visual feedback

-

Simple to operate

-

-

Limitations:

-

Manual reading susceptible to human error

-

Limited data logging

-

Requires error correction for horizontal use

-

-

-

8. Additional FAQs

-

Q: What is the operating temperature range?

-

Q: How does the gauge handle overloads, and is damage likely if overloaded?

-

Q: Are mounting fixtures or accessories available for hands-free testing?

-

Q: How does a rod-type gauge compare to an electronic force gauge in repeatability and data recording?

You may like

Ito Seisakusho JIS-K-3362 Bulk Density measurement device for synthetic detergent (100ml (φ40mm) acrylic)

Contact

Ito Seisakusho JIS-K-6720 Bulk Density measurement device for vinyl chloride resin (100ml (φ40mm))

Contact