MIDORI PRECISIONS LP-50F 1KΩ Linear Displacement Sensor

| Manufaturer: | MIDORI PRECISIONS |

| Model: | LP-50F 1KΩ |

*The above price is Standard Price, Kindly click on Request a quote to unlock the Best Price and Delivery Date. Our expert consulting team is always ready to assist you.

*Order Process: 1. Request a quote ⇒ 2. Quote via Email ⇒ 3. Proforma Invoice ⇒ 4. Payment ⇒ 5. Delivery and Invoice.

*You can't find the product you need, please send us the picture/specifications/model/product code and quantity you need to email: [email protected]. We will find it for you.

*Review us here: Review Now

Description

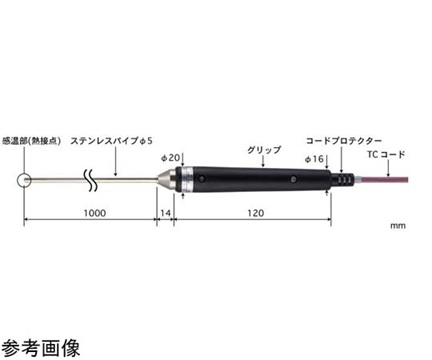

- Specifications: 50mm stroke detection

- Total resistance: 1kΩ±20%

- Effective stroke: 50mm

- Independent linearity: ±0.5% FS

- Rated power: 1.5W (70℃)

- Size: 20 x 16 x (MAX) 184mm

- Weight: Approx. 75g

- Operating temperature range: -40 to +100°C

-

Frequently Asked Questions – LP-50F 1KΩ Linear Displacement Sensor (MIDORI PRECISIONS):

-

1/ What is the LP-50F 1KΩ linear displacement sensor?

The LP-50F is a conductive-plastic potentiometer that converts linear motion into a proportional change in electrical resistance. It delivers reliable position feedback in a compact form factor.

-

2/ What industries and applications commonly use this sensor?

Typical applications include automotive testing (ejector strokes, wheel alignment), injection molding machines, vending machines, driving simulators, material position control, and general motion measurement.

-

3/ Technical Specifications

-

Parameter Value Effective Electrical Travel 50 mm Total Resistance 1 kΩ ± 20% Independent Linearity ± 0.5% FS Rated Power Dissipation 1.5 W (at 70 °C) Housing Diameter 16 mm Shaft Diameter M5 mm (standard), M3 mm (option) Operating Temperature –40 °C to +100 °C Weight Approx. 75 g 4/ Operating PrincipleThe LP-50F uses a sliding wiper over a resistive track. As the shaft moves along its travel, the wiper position changes the resistance between its two end terminals and the wiper terminal. This variable resistance can be measured directly or converted into a voltage/current signal for position feedback.

-

5/ How many wires does it have? Three wires: two ends of the resistive element and one wiper (output).

-

6/ How do I get a usable voltage or current signal? Use the sensor in a voltage divider configuration. Excite the two end terminals with a known DC voltage, then measure the wiper voltage. For current loops (4 - 20 mA), feed the wiper voltage into a signal conditioner or dedicated transmitter.

-

7/ Can I interface it directly with a PLC or data acquisition system? Yes, by pairing with a signal conditioner that outputs 0 - 5 V, 0 - 10 V, or 4 - 20 mA you can feed the position data directly into most PLC analog inputs or DAQ modules.

-

8/ What is the recommended mounting procedure?

-

- Secure the sensor body with two M3 or M4 screws, avoiding over-torque.

-

- Align the shaft axis precisely with the moving part’s travel path to prevent side loads and binding.

- Use flexible couplings or anti-rotation brackets if necessary to isolate mounting forces. -

9/ How do I protect it from dust and moisture? Fit appropriate seals or boots around the shaft interface. Keep mounting surfaces clean and consider IP-rated enclosures for harsh environments.

-

10/ How do I calibrate the sensor?

-

- Move the shaft to the mechanical zero position and record the corresponding resistance or voltage.

- - Move it to full travel (50 mm) and record the second reading.

- - Use these two data points to scale the output in your control system.

-

11/ What maintenance is required? Periodic inspection every 6 - 12 months or after 1000 hours of operation:

-

- Clean the shaft and housing of debris.

- - Apply light machine oil to the sliding surfaces.

- - Check wiring integrity and mounting bolts.

-

12/ Is there a version with a return spring? Yes, the LP-50FB adds a spring-return mechanism and can achieve ± 0.2% FS linearity.

-

13/ What option accessories are available?

-

- Mounting brackets and anti-rotation clamps

- - Dust boots and shaft seals

- - Signal conditioners for voltage/current output

- - Custom cable assemblies and connectors

-

-

14/ Where can I purchase the LP-50F? Please contact QTE Technologies (qtetech.com/en) or Kindly click on Request a quote to unlock the Best Price and Delivery Date.

-

15/ What is the warranty period? Please contact QTE Technologies (qtetech.com/en): https://qtetech.com/en/warranty-policy

-

16/ How do I request a custom variant? Please contact QTE Technologies (qtetech.com/en)

You may like

KANOMAX JAPAN 6541-21 Climomaster Anemometer Probe Wind Speed and Temperature Sensor (Directional)

Contact