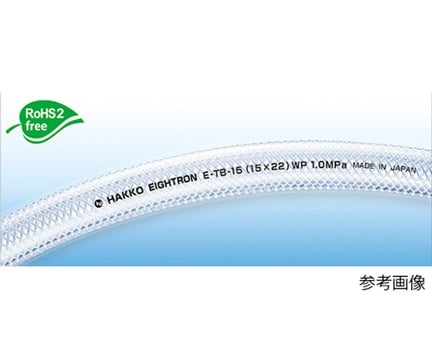

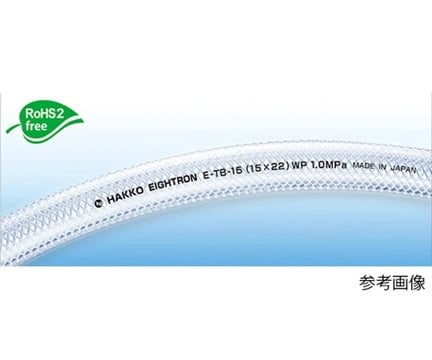

HAKKO EIGHTRON E-TB-25 Pressure hose (reinforcement polyester thread, 25 x 33mm, length 50m) for industrial in chemicals/ oil/ powder/ air, etc

| Manufaturer: | HAKKO EIGHTRON |

| Model: | E-TB-25 |

*The above price is Standard Price, Kindly click on Request a quote to unlock the Best Price and Delivery Date. Our expert consulting team is always ready to assist you.

*Order Process: 1. Request a quote ⇒ 2. Quote via Email ⇒ 3. Proforma Invoice ⇒ 4. Payment ⇒ 5. Delivery and Invoice.

*We deliver to your doorstep under DAP terms. Customs clearance is for your account.

*You can't find the product you need, please send us the picture/specifications/model/product code and quantity you need to email: [email protected]. We will find it for you.

*Review us here: Review Now

Description

- Durability: This pressure-resistant braided hose is designed for industrial and commercial use, providing excellent durability.

- Pressure resistance: Can be used up to 1.0MPa (at 20℃).

- Inner diameter x outer diameter: 25 x 33 mm

- Standard length: 50m

- Applications: Water, chemicals, oil, powder, air, etc.

- Material: Main material: soft vinyl chloride, reinforcement: polyester thread

-

Frequently Asked Questions – HAKKO EIGHTRON E-TB-25 Polyester-Reinforced PVC Hose (25 × 33 mm, 50 m Roll):

1. What is the HAKKO EIGHTRON E-TB-25 hose?

It’s a clear-blue, polyester-braided PVC pressure hose made in Japan for industrial transfer of air, water, oil, chemicals, and powder.

2. What are the hose’s key specifications?

-

Inner diameter × Outer diameter: 25 mm × 33 mm

-

Standard length: 50 m per roll

-

Maximum working pressure: 1.0 MPa (10 bar) at 20 °C

-

Temperature range: 0 °C to 60 °C

-

Minimum bend radius: 175 mm

-

Color: Transparent blue

-

3. How is the hose constructed?

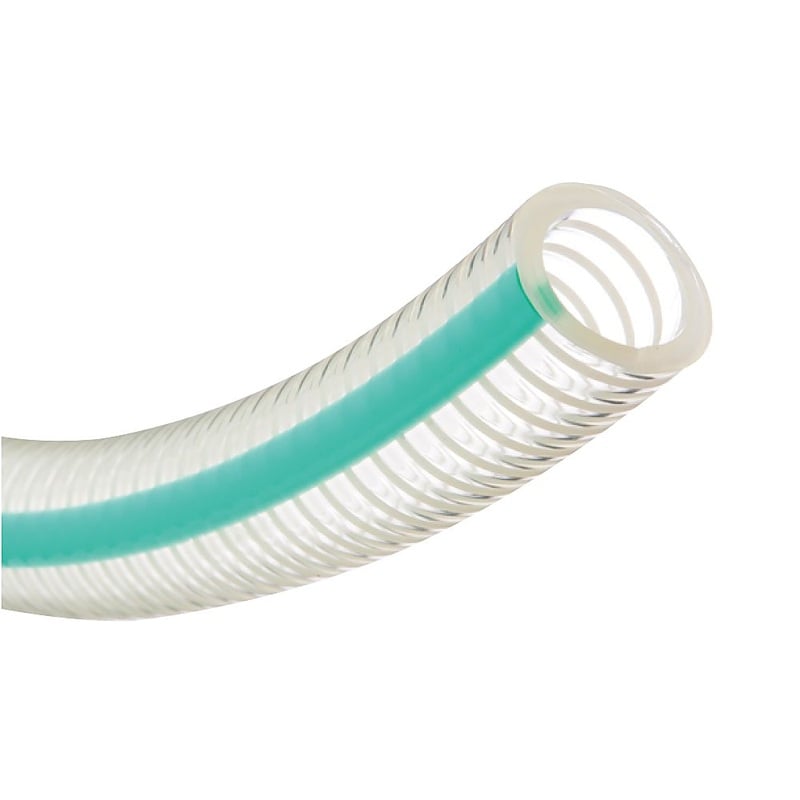

A flexible PVC tube is tightly braided with high-strength polyester fibers, combining excellent pressure resistance with remaining lightweight and pliable.

4. Which fluids can it handle?

Designed for general-purpose transfer of air, water, oil, chemicals, and fine powders. For aggressive or highly corrosive chemicals, fluorine-resin hoses are recommended instead.

5. How does it compare to a rubber hose?

Compared to conventional rubber hoses, the E-TB series is significantly lighter, more flexible, transparent for visual flow monitoring, and maintains full 1.0 MPa working pressure despite its low weight.

6. What certifications and compliance does it have?

-

RoHS compliant (EU Directive 2015/863)

-

Free of UV-328 additive

-

TSCA-compliant (no decaBDE, PIP (3:1), 2,4,6-TTBT, PCTP, or HCBD) Certificates for restricted-substance analysis available on request.

-

7. How do I cut and connect the hose?

-

The hose is marked at every meter for easy, square cuts.

-

Use sharp tubing cutters to avoid pinching.

-

Attach with Hakko E-ELB, E-ELF, or E-FTB series barbed/ferrule fittings for leak-proof joints.

-

8. How should I store and maintain it?

Keep the hose coiled in a clean, dry area away from direct sunlight and sources of heat. Avoid stacking heavy objects on it and prevent prolonged contact with strong solvents or sharp edges. No special maintenance is required.

9. What common issues might arise and how can I troubleshoot?

-

Kinking: Ensure bend radius ≥ 175 mm or use a support coil.

-

Leaks at fittings: Re-cut the hose end squarely, inspect and re-seat the fitting, or replace O-rings/seals.

-

Contamination: Flush with compatible solvent or replace the hose if residue persists.

-

10. What is its expected service life and warranty?

Under normal industrial use, hoses can last several years. Hakko typically offers warranty against manufacturing defects, please contact QTE Technologies.

11. Where can I purchase the E-TB-25 hose?

Please contact QTE Technologies.

You may like

TOYOX TR-4-100 Toyoron Hose Pressure-Resistant Hose for Water/ Oil/ Chemicals and Air (4mm x 9mm, 100m)

Contact

TOYOX TR-38-50 Toyoron Hose for Water/ Oil/ Chemicals and Air Pressure-Resistant Hose (38 x 48mm, length 50m)

Contact

HAKKO EIGHTRON E-NF-8.5 New Flex (Polyurethane, Reinforcement Polyester thread, 8.5 x 12.5mm, Standard Length 100m) for air tools

Contact

TOYOX TR-15-15 Toyoron Hose Pressure-Resistant Hose for Water/ Oil/ Chemicals and Air (15 x 22mm, length 15m)

Contact

TOYOX TGF-50-40 Heat Resistant and Pressure Resistant Hose (Reinforcement Special PET resin, 50.8mm x 62.8mm, 40m) for Transporting Food and Drinking Water

Contact