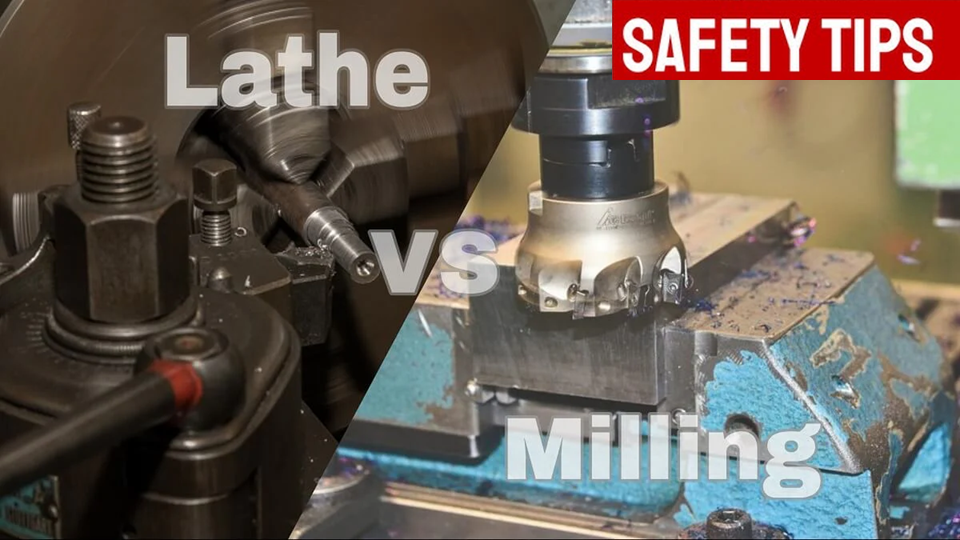

Operating a lathe poses multiple risks - from entanglement in high speed rotating parts to injuries caused by flying debris. Implementing rigorous safety measures protects both operators and equipment, ensuring precision machining and minimizing downtime.

1. Equip and Verify Personal Protective Equipment (PPE)

Always wear ANSI-approved safety glasses or a full face shield to guard against chips and splinters. Hearing protection is essential when noise exceeds 85 dB, and sturdy, closed-toe steel-toe footwear protects against falling objects.

Gloves should only be worn when handling sharp stock or tools and never during actual machining to prevent entanglement. Secure long hair and remove jewelry or loose clothing before starting the lathe.

2. Ensure Thorough Training and Supervision

New operators must complete hands-on training covering machine fundamentals, safe tool handling, and maintenance protocols. Until proficiency is demonstrated, supervision by an experienced machinist is mandatory to correct bad habits and reinforce emergency procedures.

Regular refresher sessions and documented competency checks help maintain a culture of safety and operational excellence.

3. Conduct a Rigorous Pre-Operation Inspection

Perform a 10-point pre-start checklist that includes:

-

Verifying that all guards, shields, and the chuck guard are securely in place.

-

Checking electrical connections, emergency stop (E-Stop) functionality, and lubrication levels.

-

Inspecting belts, pulleys, and sliding components for wear or damage.

Any irregularities must be addressed before powering up the machine to prevent unexpected breakdowns or accidents.

4. Secure and Center the Workpiece Accurately

Select the correct chuck or faceplate based on material shape and dimensions. Align the workpiece precisely in the chuck jaws, apply uniform torque to avoid off-center rotation, and perform a low-speed run-in to confirm stability.

For longer or slender stock, use a tailstock or steady rest to prevent whipping and improve surface finish. Always double-check alignment with dial indicators when high tolerance is required.

5. Utilize and Maintain Safety Guards Properly

The chuck guard and workpiece shield protect the operator from pinch points, entanglement, and flying projectiles. Inspect these guards daily for cracks, deformation, or wear and ensure they latch securely without impeding tool changes.

Never operate the lathe with guard components removed - doing so exponentially increases the risk of severe injuries.

6. Select, Maintain, and Sharpen Cutting Tools

Use tool materials and geometries optimized for the workpiece material (e.g., carbide inserts for steels, high-speed steel for general use). Sharpen cutting edges to factory specifications and inspect tools for micro-cracks or chipping before each setup.

A dull or damaged tool increases cutting forces, amplifies vibration, and diminishes surface finish, all of which elevate the danger of tool breakage.

7. Control Spindle Speed and Feed Rate

Set spindle speeds according to the formula RPM. Start at lower RPMs - especially below 1,000 - for thin or unbalanced stock to allow quick emergency stops.

Match feed rates to the desired surface finish and tool geometry. Excessive feeds can overload the tool and amplify vibration, while too low feeds may cause rubbing and work hardening.

8. Maintain an Organized, Distraction-Free Workspace

Keep the area around the lathe clear of chips, oil spills, and unused tools. Use a brush or compressed air (below 30psi) to remove swarf - never your hands - to avoid lacerations and entanglement.

Store wrenches, chuck keys, and calipers away from the machine bed before starting the spindle. Removing these tools prevents them from becoming hazardous projectiles.

9. Prepare for Emergencies and Schedule Regular Maintenance

Locate and test the E-Stop button before each shift to ensure immediate machine shutdown capability. Practice emergency drills periodically so operators develop muscle memory for crisis response.

Implement a preventive maintenance plan that includes bearing lubrication, belt tension checks, and electrical inspections. A well-maintained lathe is less prone to unexpected failures and hazardous malfunctions.

Summary of 9 Key Safety Tips

| Tip No. | Focus Area |

|---|---|

| 1 | Personal Protective Equipment (PPE) |

| 2 | Training and Supervision |

| 3 | Pre-Operation Inspection |

| 4 | Workpiece Securing and Centering |

| 5 | Safety Guards |

| 6 | Cutting Tool Selection and Sharpening |

| 7 | Spindle Speed and Feed Control |

| 8 | Workspace Organization |

| 9 | Emergency Preparedness and Maintenance |

Adhering to these nine comprehensive tips not only safeguards operators but also extends the machine’s service life and ensures superior machining accuracy. Cultivate a proactive safety mindset and continuously refine procedures to adapt to new materials, technologies, and production demands.

By now you should know how to use a lathe safely. Buy a lathe from QTE Technologies. We are a proud global MRO provider, serving customers in over 180 countries and are dedicated to ensuring a complete and satisfying customer experience. Established in 2010, we supply over 1 million products across all industries and engineering disciplines. Additionally, you can reach us anytime via 24 x 7 chat support, phone, WhatsApp or email. Discover what our valued customers have to say about our services on our dedicated review page.

Post Author By QTE Technologies Editorial Staff (with a solid background in both technical and creative writing - accumulated 15+ years of experience).