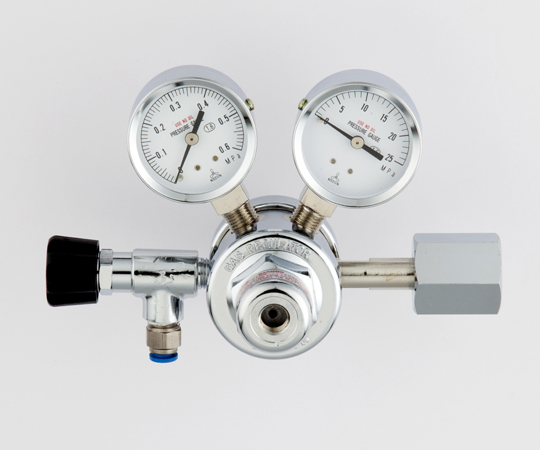

Yutaka Crown GF1-2506-RN-VAR Pressure Regulator (Gas Ar, Input / 25 MPa, Output / 0.6 MPa)

| Manufaturer: | Yutaka Crown |

| Model: | GF1-2506-RN-VAR |

*The above price is Standard Price, Kindly click on Request a quote ![]() to unlock the Best Price and Delivery Date - Check Availability. Our expert consulting team is always ready to assist you.

to unlock the Best Price and Delivery Date - Check Availability. Our expert consulting team is always ready to assist you.

*Order Process: 1. Request a quote ⇒ 2. Quote via Email ⇒ 3. Proforma Invoice ⇒ 4. Payment ⇒ 5. Delivery and Invoice.

*We deliver to your doorstep under DAP terms. Customs clearance is for your account.

*You can't find the product you need, please send us the picture/specifications/model/product code and quantity you need to email: [email protected]. We will find it for you.

*Review us here: Review Now

Description

- Side pressure meter: Input / 25 MPa Output / 0.6 MPa

- Fittings: inlet / W 22 right bag nut, exit / φ6 mm hose opening or Rc 1/4 (PT 1/4 female screw)

- pressure of use: Entrance / 14.8 MPa (MAX), Exit / 0.4 MPa (MAX)

- Material: Main / brass, Valve Sheet / Teflon R or Daifuron, Diaphragm / Nitrile Gom Teflon (R)

- flow rate: 25 L/min

- Weight: 1.5 kg

- Model number: GF1-2506-RN-V

- Type: A one-stage type with an outlet valve with an outlet valve

- Suitable gas: Ar

- GF Series

-

Frequently Asked Questions (FAQ) - Yutaka Crown GF1-2506-RN-VAR Pressure Regulator:

1. What is the GF1-2506-RN-VAR?

The GF1-2506-RN-VAR is a single-stage, cylinder-mounted precision pressure regulator designed specifically for Argon gas. Its brass construction and compact design make it ideal for lab and industrial piping applications. It accepts a high-pressure inlet (up to 25 MPa) and delivers a stable low-pressure outlet (up to 0.6 MPa)

-

2. What are its primary applications?

This regulator is tailored for physical and chemical science markets, gas distribution in labs, welding (MIG/MAG), metallurgy, optics, and any setup requiring precise Argon pressure control in piping systems.3. What are the inlet and outlet pressure specifications?

- Inlet (P1): up to 25 MPa

- Outlet (P2): adjustable from 0 up to 0.6 MPa

Maximum recommended working pressures are 14.8 MPa at the inlet and 0.4 MPa at the outlet for continuous service, per manufacturer guidance.

4. What fittings and connections does it use?

- Inlet: W22×1 right-hand cap nut for direct cylinder mounting.

- Outlet: Ø6 mm hose port or Rc1/4 (PT 1/4 female) thread These standard fittings support easy integration with common Argon supply lines and hoses.

5. What materials are used in its construction?

- Body: nickel-plated brass for corrosion resistance

- Valve sheet/seat: fluoropolymer (Teflon R) or Daiflon for chemical durability

- Diaphragm: nitrile rubber coated with PTFE for tight sealing and long service life.

6. What flow rate can it support?

Typical flow capacity is 25 L/min at the maximum outlet pressure of 0.6 MPa.

7. How much does the regulator weigh?

The GF1-2506-RN-VAR weighs approximately 1.5 kg, making it robust yet compact enough for direct cylinder mounting without undue strain on mounting hardware.

8. How accurate and repeatable is the outlet pressure?

The GF1 series delivers outlet pressure with an accuracy of +/-1 % of full-scale and excellent repeatability over multiple adjustment cycles, ensuring reliable gas delivery for sensitive processes.

9. How do I adjust the outlet pressure?

Turn the adjustment knob clockwise to increase the outlet pressure and counterclockwise to decrease it. Monitor the output pressure directly and fine-tune until the desired setting is reached.

10. What maintenance is recommended?

- Inspect all connections for leaks every 3 - 6 months using a soap-bubble test.

- Replace the diaphragm and valve seat every 12 - 18 months or immediately if any deformation or leakage is detected.

Keep the exterior clean and avoid exposure to solvents that could damage seals.

11. Can it be used with gases other than Argon?

Should only be used with Ar gas.

12. What optional accessories are available?

- Front panel or bracket mounting kits for instrument panels

- Integrated or remote pressure gauges (rear-mounted “RN” style or other variants)

Inline dust filters to protect the regulator internals

Flowmeter attachments calibrated for specific gases and flow ranges (e.g., 100 mL/min to 10 L/min).

13. What does the part number GF1-2506-RN-VAR represent?

- GF1: Series designation (single-stage precision regulator)

- 25: 25 MPa maximum inlet rating

- 06: 0.6 MPa maximum outlet rating

- RN: Rear-mounted pressure gauge port

- VAR: Variant optimized for Argon gas service

14. Where can I find detailed documentation and support?

Please contact QTE Technologies (qtetech.com/en).

15. What safety precautions should I observe?

- Always bleed downstream pressure before servicing or dismounting the regulator.

- Use only clean, dry Argon free of particulates or oil to prevent diaphragm damage.

- Ensure all fittings are tightened per torque specifications to avoid leaks.

You may like

Yutaka Crown FR-IIS-OP Series Cylinder-mounted two-stage pressure regulator (25MPa, 0~0.6MPa)

Contact

CHIYODA SEIKI BHN1-Ar Precision Pressure Regulator SRS-HS-BHN1-Ar (gas Ar) (15 MPa/ 0.1 - 0.3 MPa)

Contact

CHIYODA SEIKI BHN1-N2 Precision Pressure Regulator SRS-HS-BHN1-N2 (gas N2) (15 MPa/ 0.1 - 0.3 MPa)

Contact

CHIYODA SEIKI BHN1-O2 Precision Pressure Regulator SRS-HS-BHN1-O2 (gas O2) (15 MPa/ 0.1 - 0.3 MPa)

Contact

CHIYODA SEIKI GHN1-Ar Precision Pressure Regulator SRS-Hs-GHN1-Ar (gas Ar) (15 MPa/ 0.1 - 0.6 MPa)

Contact

CHIYODA SEIKI GHN1-N2 Precision Pressure Regulator SRS-HS-GHN1-N2 (Gas N2) (15 MPa/ 0.1 - 0.6 MPa)

Contact

CHIYODA SEIKI GHN1-O2 Precision Pressure Regulator SRS-HS-GHN1-O2 (gas O2) (15 MPa/ 0.1 - 0.6 MPa)

Contact

CHIYODA SEIKI GHSS-5H Precision Pressure Regulator (SRS-HS) (Gas O2, N2, Ar, Air, H2, He) (25 MPa/ 1.0MPa)

Contact