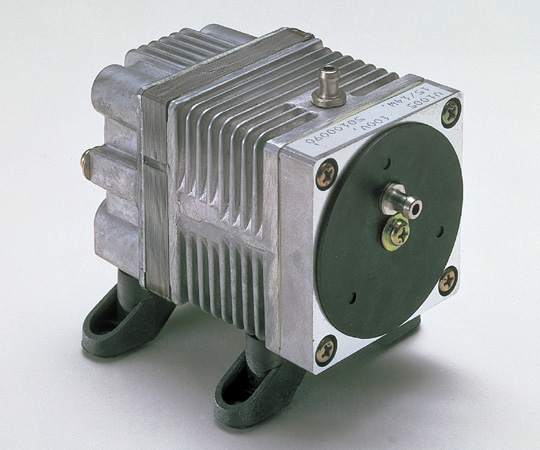

MORESCO MR-200A Vacuum Pump Oil (NEOVAC) 4L

| Manufaturer: | MORESCO |

| Model: | MR-200A |

*The above price is Standard Price, Kindly click on Request a quote to unlock the Best Price and Delivery Date. Our expert consulting team is always ready to assist you.

*Order Process: 1. Request a quote ⇒ 2. Quote via Email ⇒ 3. Proforma Invoice ⇒ 4. Payment ⇒ 5. Delivery and Invoice.

*You can't find the product you need, please send us the picture/specifications/model/product code and quantity you need to email: [email protected]. We will find it for you.

*Review us here: Review Now

Description

- Model number: MR-200A

- Capacity (L): 4

- Flash point: 252℃

- Kinematic viscosity (40℃): 71.0mm2/sec

- Pour point: -15.0℃

- Thermal stability (170℃ x 24 h): Pass

- Steaming pressure (50℃): 1.3 x 10^-3 or less (1 x 10^-5Torr)

- NEOVAC

-

Frequently Asked Questions (FAQ) – NEOVAC MORESCO MR-200A Vacuum Pump Oil:

-

1/ What is NEOVAC MR-200A and what pump types is it suitable for? The NEOVAC MR-200A is a high-performance vacuum pump oil specifically formulated for rotary vane and two-stage oil ring pumps, offering superior lubrication and sealing properties.

-

2/ What packaging sizes are available? It is available in 4 L cans, with optional 18–20 L pails or 200 L drums.

-

3/ What is the kinematic viscosity of MR-200A? The oil has a kinematic viscosity of 71 mm²/s at 40 °C, providing ideal lubrication film thickness for high-speed pump components.

-

4/ What is the vapor pressure of the oil under vacuum conditions? The vapor pressure is below 1.3 × 10⁻³ Pa at 50 °C, ensuring deep vacuum performance with minimal backstreaming.

-

5/ What are the flash point and pour point of the oil? MR-200A has a high flash point of 256 °C and a pour point below –11 °C, allowing stable operation over a wide temperature range.

-

6/ How does MR-200A resist oxidation and thermal degradation? The oil features excellent oxidation inhibitors and thermal stability, preventing sludge formation and maintaining fluid integrity during prolonged high-temperature use.

-

7/ How should the oil be stored and handled? Store in a cool, dry place away from direct sunlight. Use a filter funnel when refilling to avoid contamination, and keep containers sealed when not in use.

-

8/ What maintenance interval is recommended for oil changes? Under normal industrial conditions, replace the oil every 2 000–3 000 operating hours or sooner if contamination or viscosity changes are detected, to maintain optimal pump performance.

-

9/ Are there any fluids MR-200A is incompatible with? MR-200A must not be mixed with water, silicone, or other incompatible fluids. Confirm the correct oil type for your pump model to avoid performance issues.

-

10/ What are the benefits of using MR-200A over standard pump oils? Its low vapor pressure, high thermal stability, outstanding anti-oxidation properties, and rapid moisture separation extend pump service life, reduce maintenance costs, and ensure consistent vacuum performance.