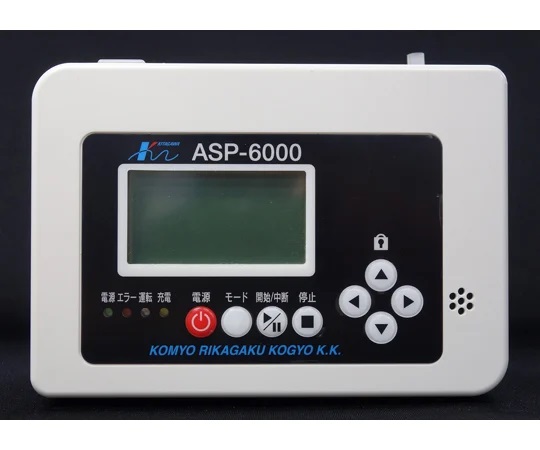

GASTEC GV-110S Gas Sampler Set (with Counter)

| Manufaturer: | GASTEC |

| Model: | GV-110S |

*The above price is Standard Price, Kindly click on Request a quote ![]() to unlock the Best Price and Delivery Date - Check Availability. Our expert consulting team is always ready to assist you.

to unlock the Best Price and Delivery Date - Check Availability. Our expert consulting team is always ready to assist you.

*Order Process: 1. Request a quote ⇒ 2. Quote via Email ⇒ 3. Proforma Invoice ⇒ 4. Payment ⇒ 5. Delivery and Invoice.

*We deliver to your doorstep under DAP terms. Customs clearance is for your account.

*You can't find the product you need, please send us the picture/specifications/model/product code and quantity you need to email: [email protected]. We will find it for you.

*Review us here: Review Now

Description

- Just pull the handle and you will instantly know the gas concentration.

- Equipped with a counter function, it is possible to easily measure detection tubes that require a large number of suctions.

- Comes in handy case/counter included

- Accessories: Complete set of accessories (grease, inlet rubber)

-

Frequently Asked Questions about GASTEC GV-110S Gas Sampling Pump (With Stroke Counter):

1. General Overview

-

1.1/ What is the GASTEC GV-110S gas sampling pump? The GV-110S is a handheld, non-sparking gas sampling pump with an integrated stroke counter, designed for rapid on-site detection using GASTEC detector tubes.

-

1.2/ How does the built-in stroke counter improve sampling? The automatic counter tracks up to 10 full pump strokes, eliminating counting errors—especially when tubes require multiple strokes.

-

2. Kit Contents & Standard Accessories

-

2.1/ What comes in the standard GV-110S kit?

-

GV-110S pump with stroke counter

-

Semi-rigid carrying case with adjustable shoulder strap

-

Multi-language instruction manual

-

Spare parts kit: 1 tube lubricant and 3 rubber inlet holders with filters

-

GASTEC Detector Tube Handbook

-

Accessories brochure

-

-

2.2/ Which pump accessories are included for immediate use?

-

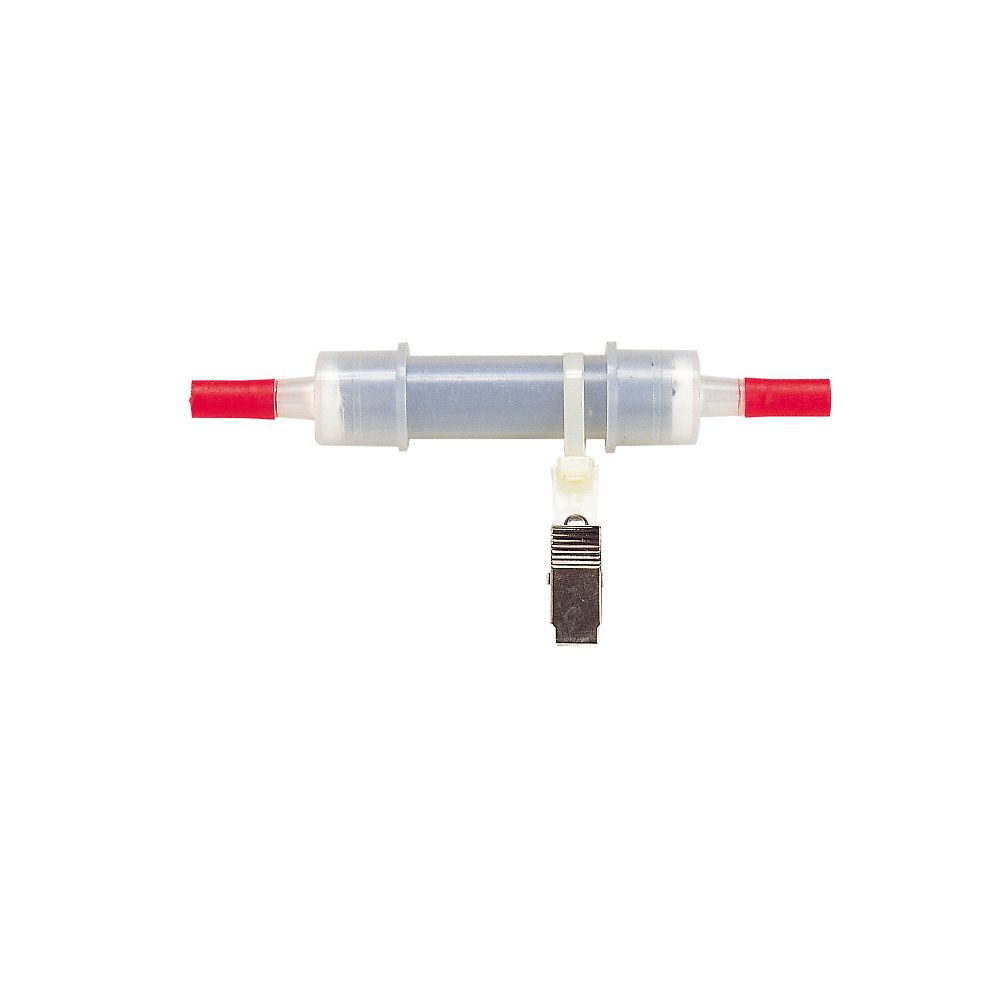

Three replacement rubber inlets

-

Specialized lubricant for piston maintenance

-

Instruction sheet

-

Compact carrying case with shoulder strap for field work

-

-

3. Optional & Replacement Accessories

-

3.1/ What optional accessories can I add?

-

Extension hoses (No. 351A-5/351A-10/351A-30) for confined-space sampling

-

Tube tip holder (No. 722) doubles as a tube breaker and glass-fragment container

-

Twin tube holder (GV500) for simultaneous measurements

-

Reusable rubber caps (DTP-1-20/DTP-2-20) for extra safety

-

One-hand operation adapter (GV-700) to lock 50 ml/100 ml strokes with one hand

-

Hot probe (No. 340) and holder (No. 345A) for sampling hot gases up to 600 °C

-

Extension pole (No. 350BP-2) for horizontal/vertical reach

-

-

4. Operation & Sampling Procedure

-

4.1/ How do I perform a sampling run?

-

Break off both ends of a fresh detector tube with the tube tip breaker or holder.

-

Insert the tube firmly into the rubber inlet and align guide marks (red lines).

-

Pull the handle to the full-stroke position (100 ml) or half-stroke (50 ml) as marked.

-

Count pump strokes via the counter display.

-

After sampling, read the color change on the tube against its calibration scale.

-

-

4.2/ What is the sample volume per pump stroke?

-

Half-stroke: 50 ml

-

Full stroke: 100 ml Total sampling volume = (number of full strokes × 100 ml) + (number of half-strokes × 50 ml).

-

-

5. Maintenance & Troubleshooting

-

5.1/ How do I check the pump’s airtightness? Before each use, lock the handle at full stroke, wait one minute, then unlock slowly. If the handle springs back or the flow-finish indicator doesn’t pop out, inspect and replace seals or O-rings.

-

5.2/ How should I lubricate and replace seals?

-

Wipe the piston and cylinder clean.

-

Apply a thin, even coat of the supplied GASTEC lubricant to the O-ring.

-

Replace O-rings or inlet holders when worn to maintain airtight performance.

-

-

5.3/ What if the counter doesn’t advance correctly?

-

Ensure you’re not holding the counter assembly during pumping.

-

Check for debris in the counting mechanism and gently clean with a dry brush.

-

Contact an service center if the issue persists.

-

-

6. Compatibility & Applications

-

6.1/ Which detector tubes are compatible with GV-110S? Over 350 GASTEC detector tubes covering 100+ gases and vapors, including CO, CO₂, NO₂, SO₂, VOCs and more.

-

6.2/ What are typical applications for this pump?

-

Field air-quality monitoring

-

Industrial hygiene and confined-space safety

-

Environmental research and rapid VOC assessment

-

Emergency response and leak detection

-