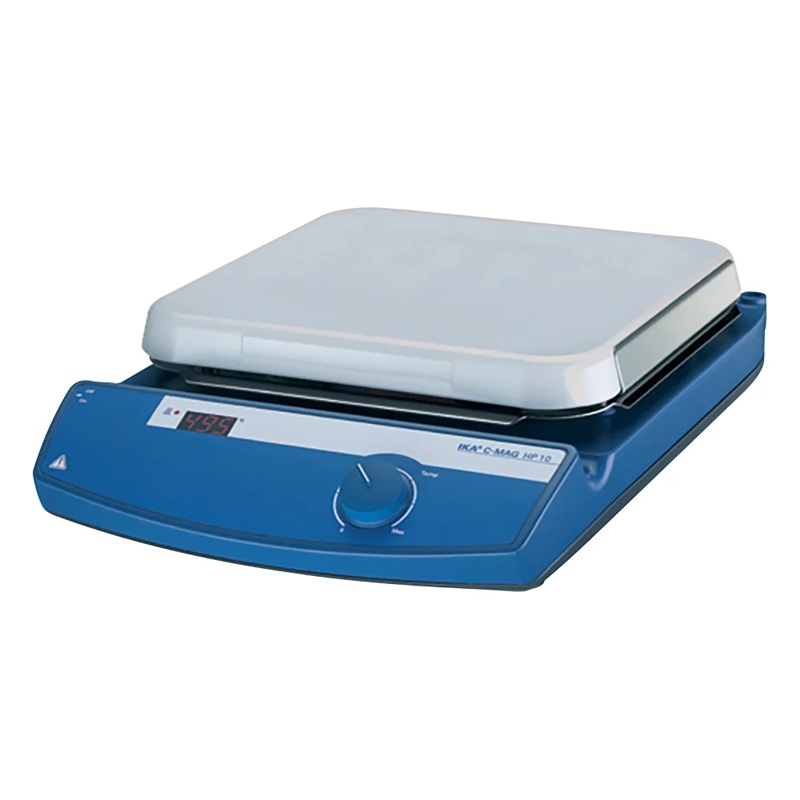

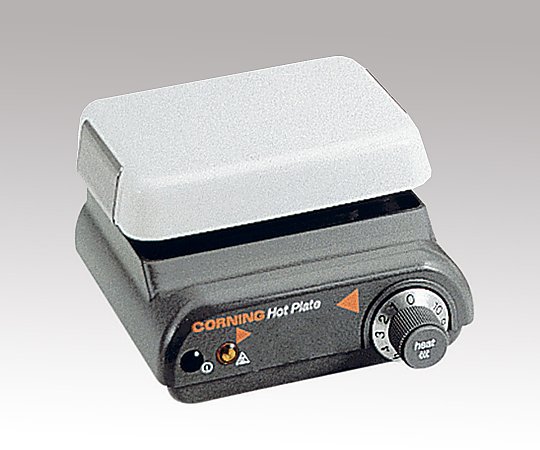

AS ONE 1-5170-81 HI-1000G Neo Hot Plate (300oC, 230VAC, PID)

| Manufaturer: | AS ONE |

| Model: | HI-1000G |

*The above price is Standard Price, Kindly click on Request a quote to unlock the Best Price and Delivery Date. Our expert consulting team is always ready to assist you.

*Order Process: 1. Request a quote ⇒ 2. Quote via Email ⇒ 3. Proforma Invoice ⇒ 4. Payment ⇒ 5. Delivery and Invoice.

*We deliver to your doorstep under DAP terms. Customs clearance is for your account.

*You can't find the product you need, please send us the picture/specifications/model/product code and quantity you need to email: [email protected]. We will find it for you.

*Review us here: Review Now

Description

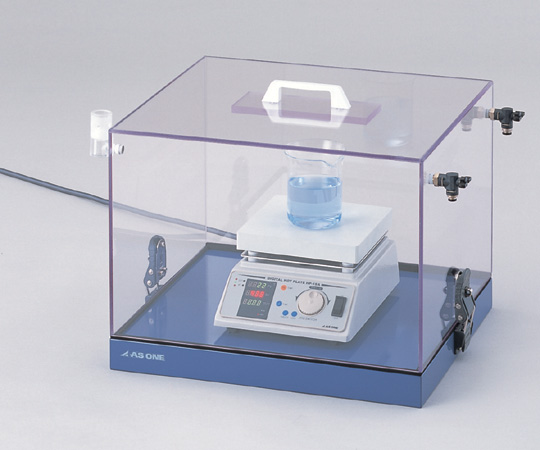

- This is a general-purpose hot plate that can withstand temperatures up to 300°C.

- Maximum temperature: 300℃

- Tabletop size: 400 x 300 mm

- Top material: Aluminum

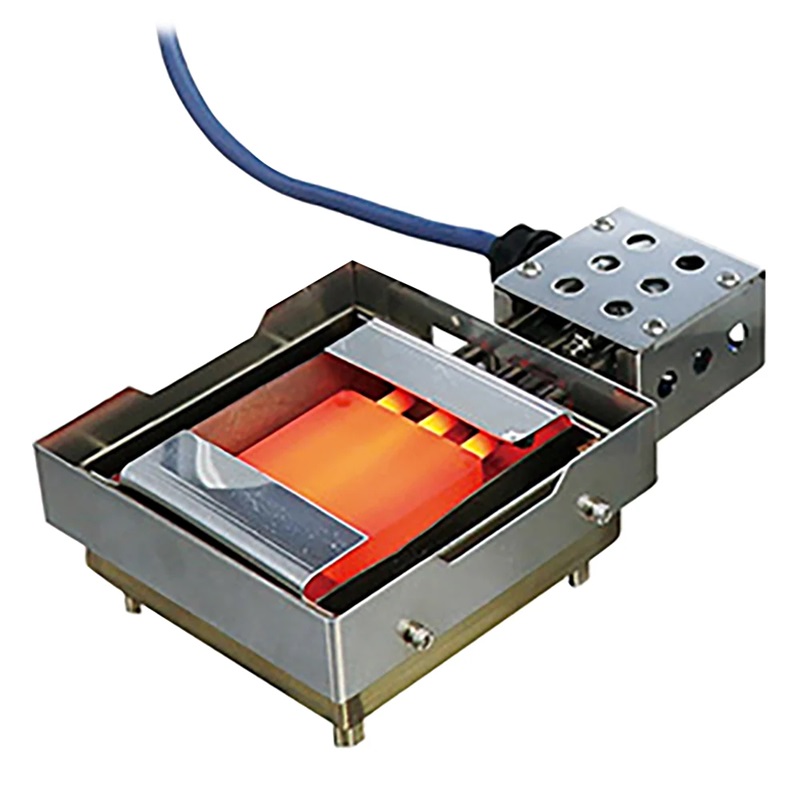

- Control method: PID control

- Temperature distribution width: 10℃ (at300℃)

- Body size: 450 x 350 x 135mm

- Heater capacity: 1600W

- Power supply: Single phase 230V±5%

- Load capacity: Approx. 10kg

- Weight: 8kg

- Country of Origin: Japan

- This product is available for inspection and testing services. Please feel free to contact us.

- *The inspection and testing service involves inspecting control-related items (such as the actual temperature inside the warehouse) and motor-related items at the time of shipment and issuing an inspection certificate.

-

Frequently Asked Questions (FAQ) for the AS ONE 1-5170-81 HI-1000G Multi-Purpose Laboratory Hot Plate (300 °C, 230 VAC, PID):

1. What is the AS ONE HI-1000G hot plate?

The HI-1000G is a universal laboratory hot plate designed for precise heating up to 300 °C. It combines a large aluminum heating surface with a PID control system and built-in timer functions, making it ideal for chemical, biological, materials-science, and semiconductor prep work.

2. What are its key specifications?

Specification Details Model 1-5170-81 HI-1000G Service temperature range Room temperature + 5 to 300 °C Temperature display accuracy ± 2 °C Heating-plate dimensions (W×D) 400 × 300 mm Plate material Aluminum Control system PID control Temperature distribution width Within 4 °C Heater capacity 900 W Power supply AC 230 V ± 15 %, 50/60 Hz, single-phase Load capacity Approx. 10 kg Unit dimensions (W×D×H) 450 × 350 × 135 mm Weight 8 kg 3. How does PID control work and why is it beneficial?

PID (Proportional–Integral–Derivative) control continuously monitors the difference between setpoint and actual temperature, automatically adjusting heater power to minimize overshoot and oscillation. This delivers fast stabilization and highly repeatable temperature profiles, crucial for sensitive experiments.

4. What timer modes does it support?

The HI-1000G offers three timer functions for automated workflows:

-

ON timer: delay auto-start of heating

-

OFF timer: auto-shutoff after a set duration

-

SV-OFF timer: heat until setpoint is reached, then countdown and shut off These modes help streamline sample prep and free you from manual monitoring.

-

5. What safety features are included?

-

Manual-reset over-temperature cutout for heater protection

-

Built-in thermal fuse to prevent runaway heating

-

Ground-fault protection requiring a properly grounded AC outlet These layers safeguard both samples and users during high-temperature operation.

-

6. How do I set up and operate the hot plate?

-

Ensure the main power switch is OFF and plug the unit into a 230 VAC outlet with protective earth.

-

Turn on the power switch; the display illuminates.

-

Use the keypad or dial to set desired temperature (0–300 °C) and select a timer mode if needed.

-

Allow the plate to heat - PID control will stabilize at setpoint.

-

After use, switch OFF the unit and unplug before cleaning or storage.

-

7. What are the power requirements and consumption?

The heater draws approximately 900 W at full output and operates from a single-phase 230 VAC ± 15 % supply at 50/60 Hz. Stable input voltage and proper grounding are mandatory to avoid damage or safety hazards.

8. What maximum load can the heating plate support?

The robust aluminum surface carries up to about 10 kg of sample vessel weight without degrading temperature uniformity or structural integrity.

9. How uniform is the temperature across the plate?

At a setpoint of 300 °C, the plate’s temperature variation remains within 4 °C from center to edge, ensuring consistent heating of multiple or larger samples simultaneously.

10. What routine maintenance does the HI-1000G require?

-

Wipe the cooled plate surface with a soft, damp cloth - avoid harsh solvents.

-

Inspect and replace the manual-reset thermal fuse and power cord annually.

-

Verify temperature accuracy yearly with a calibrated thermometer and recalibrate if drift exceeds ± 4 °C.

-

11. What environment is recommended for safe operation?

Use in a ventilated lab at 5–40 °C ambient temperature and ≤80 % relative humidity (non-condensing). Keep at least 10 cm clearance around the unit to ensure proper heat dissipation.

12. Where can I obtain service, parts, or technical support?

Contact QTE Technologies (qtetech.com/en)