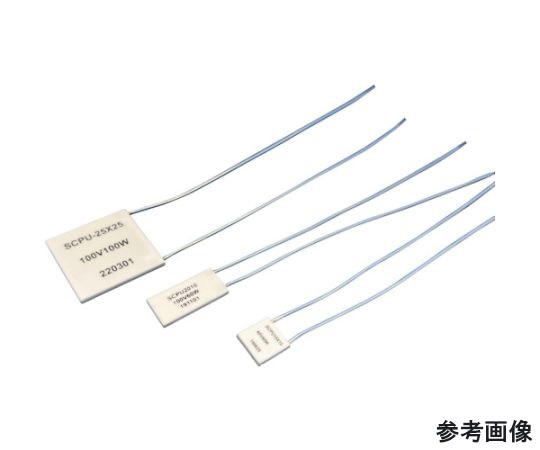

AS ONE 1-1177-01 Silicone Rubber Heater MG 250mm x 50mm

| Manufaturer: | AS ONE/ Others |

*The above price is Standard Price, Kindly click on Request a quote to unlock the Best Price and Delivery Date. Our expert consulting team is always ready to assist you.

*Order Process: 1. Request a quote ⇒ 2. Quote via Email ⇒ 3. Proforma Invoice ⇒ 4. Payment ⇒ 5. Delivery and Invoice.

*You can't find the product you need, please send us the picture/specifications/model/product code and quantity you need to email: [email protected]. We will find it for you.

*Review us here: Review Now

Description

- Width x length: 250mm x 50mm

- Used temperature: Regular operating temperature/200℃, Highest temperature/250℃

- Rating voltage: AC100V

- Capacity tolerance: +/- 10%

- Power density: 0.5W/cm2 (100VAC)

- Insulation resistance value: 100MΩ or more/500VDC

- Withstand voltage: 1500V/1 minute

- Lead wire length: 300mm

- Magnetization force: 0.04T

- Thickness: 1.5mm

- *Please use with close to the object to be heated.

- *It is not a temperature self control type, Depending on the situation, attach an temperature controller, etc., Use as the surface temperature to be definitely 200℃ or less.

- *Waterproof function is not available. Do not directly put into liquid.

-

Frequently Asked Questions for AS ONE O&M Heater 1-1177-01 Silicone Rubber Heater Sheet (250 mm × 50 mm):

1. What is the AS ONE O&M Heater 1-1177-01?

This product is a flexible silicone rubber heater sheet sized 250 mm × 50 mm. It embeds nickel–chrome resistance wire inside a high-temperature silicone matrix to deliver rapid, uniform surface heating for laboratory and industrial applications.

2. What are its key features?

-

Uniform heat distribution across the entire 250 × 50 mm area

-

Thin and flexible profile (approx. 1.5 mm thick) conforms to curved or flat surfaces

-

High power density (typically 0.8–1.0 W/cm²) for fast warm-up

-

Operating temperature range from –60 °C up to +250 °C

-

Electrical insulation resistance ≥ 5 MΩ and dielectric strength ≥ 2 000 V (5 s)

-

Built-in end-of-line wiring for easy connection to controllers

-

3. What are the detailed specifications?

Specification Value Dimensions (W × L × T) 250 mm × 50 mm × approx. 1.5 mm Power Rating 100 W (customizable 50–300 W) Power Density 0.8–1.0 W/cm² Voltage Options 110 VAC or 220 VAC Temperature Range –60 °C to +250 °C Insulation Resistance ≥ 5 MΩ Dielectric Strength ≥ 2 000 V, 5 s Compression Strength Approx. 100 kg/cm² Material Silicone rubber, fiberglass cloth, Ni–Cr wire Weight ~ 100 g Model Number 1-1177-01 4. How do I install and wire the heater sheet? -

Clean and dry the application surface; remove oils or contaminants.

-

Affix the heater sheet using high-temperature silicone adhesive or specialized heat-resistant tape.

-

Connect the two lead wires to a PID controller or on/off thermostat rated for the chosen voltage.

-

Ensure proper grounding of the heater’s metal backing or housing.

-

Optionally attach a K-type thermocouple or PT100 sensor directly to the heater surface for closed-loop control.

-

5. How is temperature controlled?

-

Use a PID temperature controller: set your desired setpoint and tune PID parameters (P, I, D) for stable response.

-

For simpler applications, an on/off thermostat with hysteresis control can maintain safe operation.

-

Always place the temperature sensor as close as possible to the heater-surface interface for accurate feedback.

-

6. What maintenance and cleaning are required?

-

Always power off and allow the heater to cool before handling.

-

Wipe the silicone surface with a soft cloth; use mild soap if necessary.

-

Avoid solvents or harsh chemicals that may degrade the silicone.

-

Inspect for cuts or abrasions periodically; replace if the internal wiring is exposed.

-

7. What troubleshooting tips should I know?

-

Heater does not warm up: verify incoming voltage, check fuse or circuit breaker, measure resistance of the heater (matches datasheet value).

-

Temperature overshoots or oscillates: retune PID parameters or switch to a controller with shorter cycle time.

-

Uneven heating: ensure full surface contact and remove any air gaps under the heater.

-

Physical damage (tears, exposed wire): discontinue use immediately and replace the heater.

-

8. How do I order and what is the warranty?

-

Model: AS ONE O&M Heater 1-1177-01 (250 × 50 mm silicone heater sheet)

-

Contact QTE Technologies (qtetech.com/en).

-

Typical lead time: 2–4 weeks for stock items; customizable variants may take longer.

-

Warranty: 12 months against manufacturing defects (excludes damage from misuse or overheat).

-

QTE Technologies is a proud global MRO provider, serving customers in over 180 countries and always striving to ensure a complete and satisfying customer experience. Established in 2010, we supply over 1 million products for every industry and technology. Additionally, you can reach us anytime via 24×7 chat support, phone, WhatsApp or email. Discover what our valued customers have to say about our services on our dedicated review page.

-

9. Can I customize dimensions or power ratings?

Yes. AS ONE offers custom silicone heater designs:

-

Any size up to 500 × 500 mm or larger (by special request)

-

Power densities from 0.5 to 2.0 W/cm²

-

Integrated cutouts, mounting holes, or connector types

-

Pre-embedded temperature sensors and over-temperature limit switches

-

Please provide a detailed specification or drawing when requesting a quotation.

10. What safety precautions should I follow?

-

Always use an appropriately sized fuse or over-current protection device.

-

Do not exceed the maximum rated voltage or temperature.

-

Ensure the heater and controller are installed in a well-ventilated area.

-

Keep flammable materials away from the heater surface.

-

Do not fold or excessively crease the silicone sheet during installation.

You may like